Case

New robotic technology for proactive cleaning of ships

A completely new innovation for keeping the hulls of large vessels free from fouling. With Semcon as a technology partner, Jotun, the world leader in marine coatings, is contributing to reduced emissions and healthier oceans through its revolutionary Hull Skating Solutions (HSS).

CustomerJotun

IndustryIndustry

CompetencesDigital SolutionsProduct DevelopmentStrategic Business Design

Background

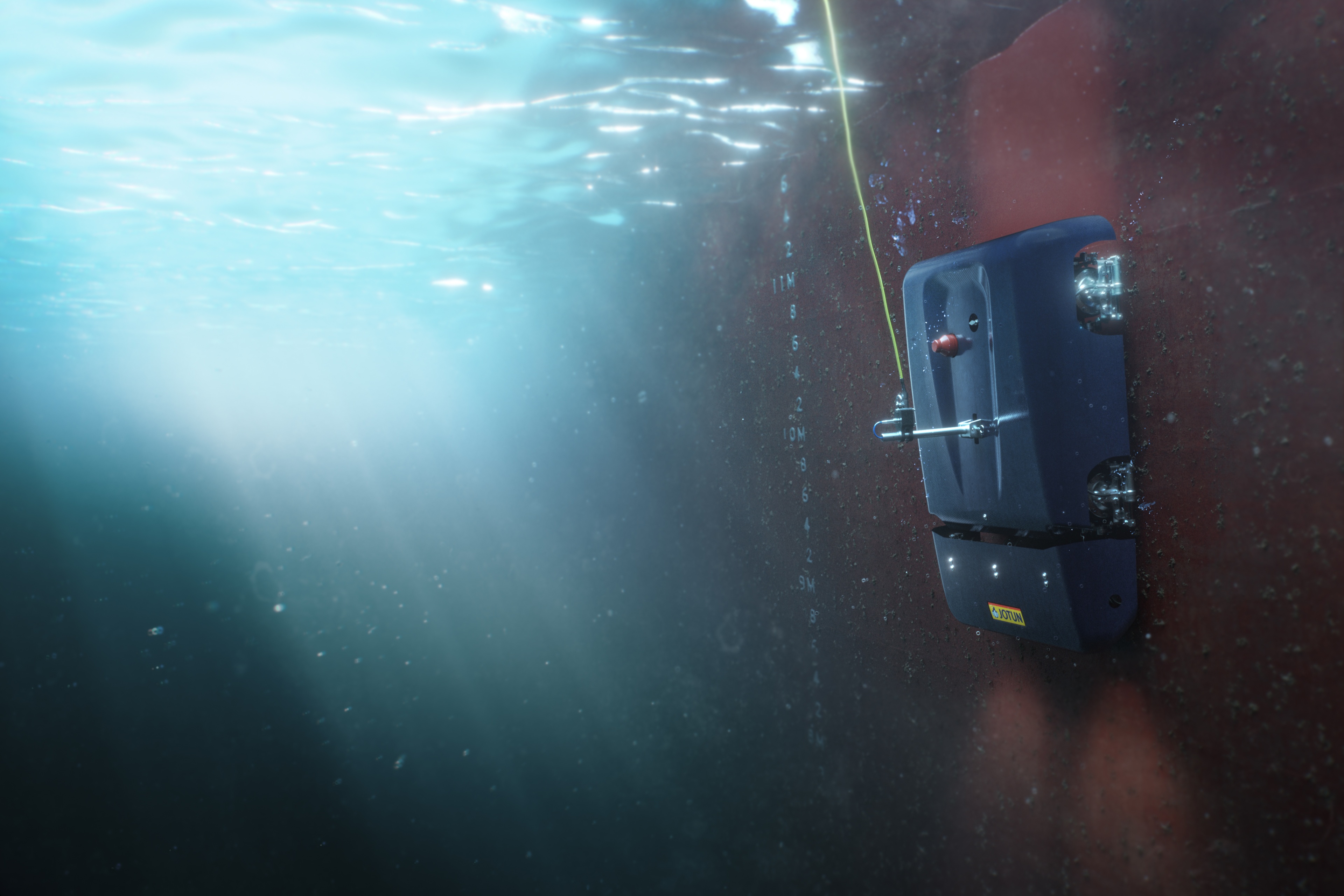

One part of HSS is the Jotun HullSkater, a remotely operated vehicle that inspects the hull underwater and keeps the hull free from fouling. The vehicle is specially developed for the inspection and preventive cleaning of vessels in challenging conditions. It is always on board the vessel, ready to do its job whenever the ship is idle. This provides shipping companies with increased operational flexibility as well as a smaller environmental footprint.

With Jotun’s new solution for proactive cleaning, emissions from a typical bulk carrier can be reduced by 22,000 tonnes of CO2, or 12.5%, over a 60-month period. This is equivalent to an overall cost saving of USD 4 million. In addition, it reduces the spread of aquatic invasive organisms between different ports.

Semcon has been part of the development of the Jotun HullSkater from the early start and has been responsible for feasibility and concept studies, mechanical design, structural and dynamic analysis, control system design, software development, electronics development, prototype manufacturing and testing.

Facts about the HullSkater:

Dimensions: 1600 x 1000 mm. Weight approx. 200 kg

4 magnetic wheels for optimum grip on the hull. Each wheel has its own motor.

4 cameras and “real time” data analysis provide the operator with information for navigation and to document the fouling on the hull.

The vehicle is connected to the operator’s control centre trough an “umbilical”, and can be operated remotely from any location in the world with 4G coverage.

Inspection and proactive cleaning of a hull will normally take around 2 to 8 hours depending on size and condition.

Semcon’s competencies in the project:

Concept and product design

System architecture

Control system design

Software development

Electronics

Testing and data analysis

Product information in the form of user manuals

About the Hull Skating Solution

Jotun has developed the revolutionary proactive cleaning solution for the most challenging operations. A primary component of Jotun Hull Skating Solutions is the unique, on-board Jotun HullSkater, the first robotic technology that has been designed for proactive cleaning. Partners involved: Kongsberg, Semcon, DNV GL, Telenor, Wallenius Wilhelmsen.