Simulation & Analysis (CAE)

Very few companies today have come so far as to implement a truly virtual product development process. However, there are plenty of benefits to explore. Through simulation and analysis, you can predict behaviour, increase efficiency, and foresee and mitigate risks before you even have a physical product.

Computer-Aided Engineering (CAE)

The advantage of computer-aided engineering (CAE) is that it predicts the behaviour of a product or process early in the design process to define design requirements, function and quality, while optimising efficiency. By implementing a simulation (CAE) driven development process, Semcon supports customers in optimising product performance and at the same time reducing time to market and quality risks. Semcon’s technical experts also assist in analysing and setting requirements to ensure the expected function going forward.

Our offering within CAE is divided into two areas: finite element analysis (FEA) and computational fluid dynamics (CFD). Both areas are powerful on their own. However, structural and fluid simulation models can be combined into a fluid-structure interaction (FSI) model to provide a more comprehensive virtual model.

Finite Element Method (FEM) & Finite Element Analysis (FEA)

The finite element method is one of the most frequently used tools today to predict physical behaviour in different industries and applications. By creating virtual simulation models, predictions of stresses, deformations and other structural reactions during operation can be made efficiently. Finite element analysis (FEA) most frequently deals with static conditions, but dynamic conditions such as vibration, shock and impact are also handled.

The main benefit of FEA is to increase product knowledge early in the development process, for example, by comparing concepts in relation to different requirements to choose the most suitable one to proceed with. FEA is also powerful in predicting and visualising product behaviour during later development stages to investigate “what if” scenarios in the design iterations.

At Semcon, we provide services in the field of FEA with a highly skilled engineering team with extensive experience in different industries and applications. Some examples of areas in which we can provide support include:

Structural/strength analysis

Dynamic analysis (vibrations)

Dynamic analysis (impact, drop test, shock)

Structural optimisation

Pipe and pressure vessel analysis

Fatigue analysis

Thermo-mechanical analysis

Weld evaluation

Electromagnetics

Evaluations according to standards such as Eurocode, ASME, ANSI, ASCE, etc.

FE simulations are done with several different software applications throughout the industry and are dependent on customer demand and/or case requirements. Semcon has the ability to use a wide range of commercial software within our organisation, such as Ansa, Meta, Abaqus, Ansys, LS-Dyna and many more.

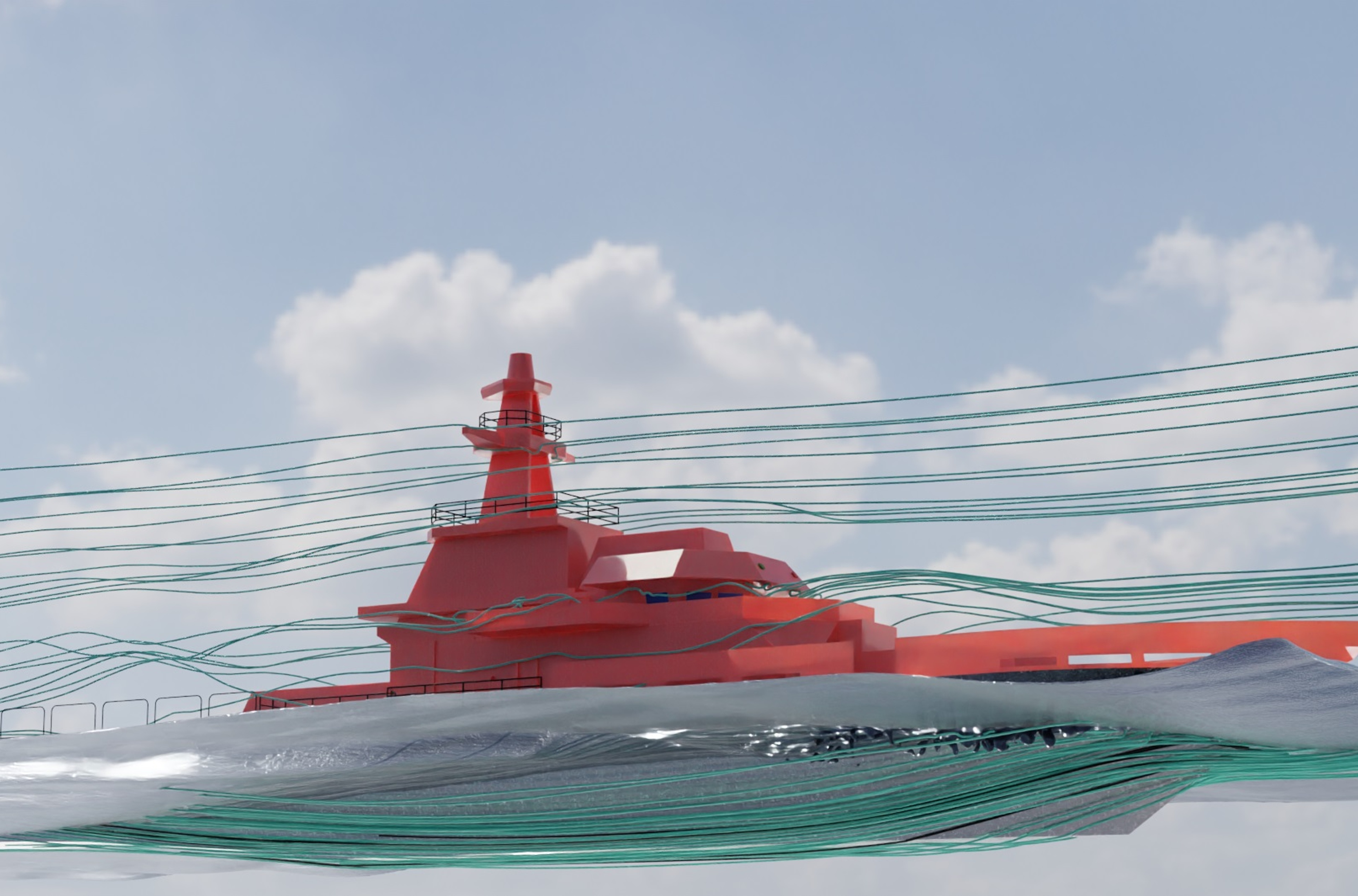

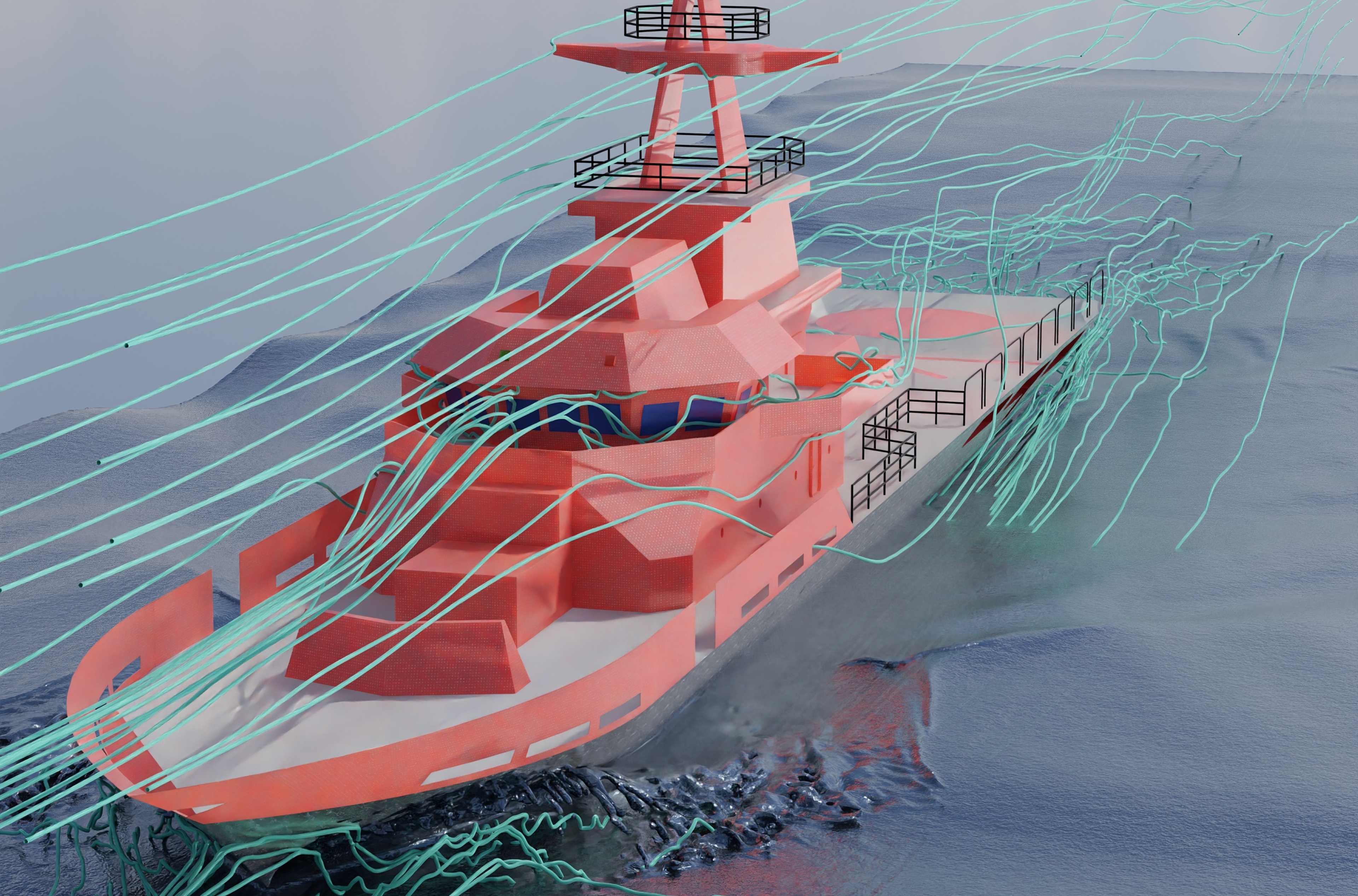

Computational Fluid Dynamics (CFD)

Computational fluid dynamics simulations provide valuable insight into your product by visualising fluid-flow phenomena. These will help you to identify and solve potential problems early on in the product development process and thereby reduce development time and cost. Often, the most promising concept can be selected based on CFD simulations long before a physical prototype is available.

Complex fluid behaviour, such as turbulence, heat transfer, mixing, combustion and multi-phase flows, can be investigated. Simulations can be performed on a component level as well as for a complete system.

Our experts at Semcon have a proven track record from CFD simulations within several industries and applications, including:

Automotive

Energy

Process industry

Life science

Semcon can access all of the state-of-the-art CFD tools, the choice of which is dependent on customer preference and the problem at hand. Typical software packages we use include Siemens Simcenter STAR-CCM+, Ansys Fluent/CFX, GT-Suite, Matlab/Simulink and OpenFOAM.