Case

Supporting Sporveien’s journey to a data-driven and future-proof workshop

The Norwegian public transport organisation Sporveien is on a digitalisation journey. The aim is a fully data-driven workshop, utilising the power of simulation, data analysis and condition-based monitoring to work more efficiently, challenge existing maintenance cycles to increase uptime and use less resources. Semcon is supporting Sporveien with expertise ranging from strategic planning, to software development and hardware analysis. And the cooperation is already paying off.

CustomerSporveien

IndustryPublic sector

CompetencesSimulation & Analysis (CAE)Strategic Business DesignData Management & AIProduct DevelopmentMechanical EngineeringSoftware Development

Background

A data-driven set-up enables the transition from periodic maintenance to condition-based monitoring. Most of us are used to periodic maintenance – after a predetermined number of miles or years, your car or machine signals that it needs service. However, condition-based monitoring is based on real-time data from sensors that track the condition of the product. The difference? Maintenance is enabled when needed rather than when scheduled. “Done correctly, digitalisation can be a driving force in the transition to a more sustainable society. It’s all about how you collect and use your data. Sporveien is a great example of a traditional workshop taking the next step towards smarter and more sustainable ways of working,” says Thor André Dugstad, Key Account Manager at Semcon.

Challenge

Done correctly, digitalisation can be a driving force in the transition to a more sustainable society.

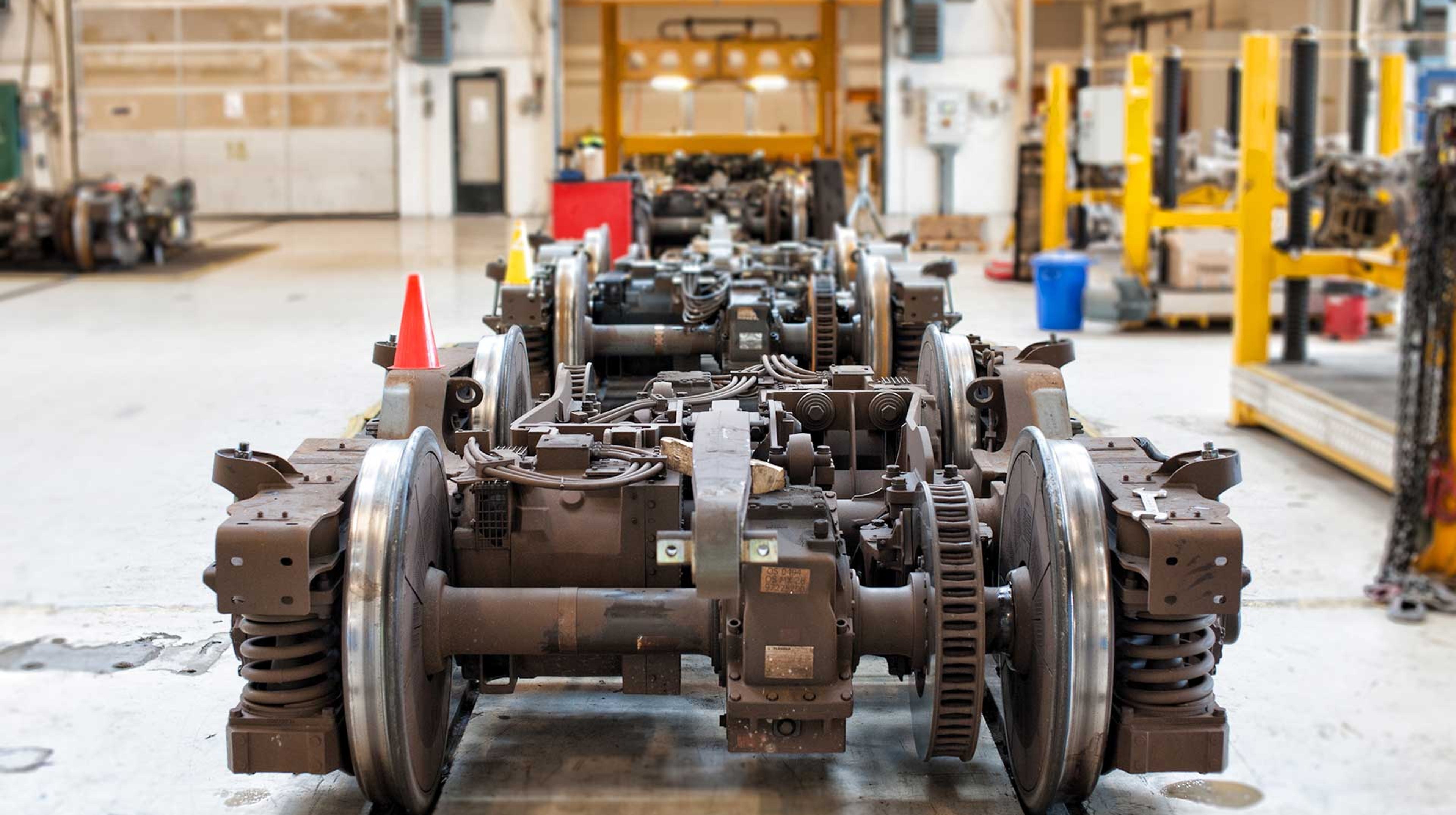

In a first joint project, Sporveien wanted to investigate if they could extend the life of the gearboxes in their underground carriages. This is a component that requires complex maintenance, regarding both specific tools and competencies. Would it be possible to prolong their maintenance cycles? Using sensor technology, the Semcon team collected data from the Oslo Metro traffic, which was then correlated with other measurements to create a simulation to understand the wear of gearbox bearings.

Solution

Based on the simulation outcome, the maintenance cycle of the gearbox bearings could be prolonged from 16 to 57 years and the use of materials and resources could be reduced significantly. Not having to replace the gearbox bearings of the underground carriages as scheduled is estimated to save Sporveien somewhere between NOK 200-300 million.

New opportunities in a data-driven era

There are many benefits to a data-driven workshop set-up. It is a means to upgrade and streamline ways of working as well as challenge traditional maintenance cycles. Just imagine all the different components that could be monitored in a single underground train or tram! In the case of Sporveien, there are many more great possibilities ahead.

Besides challenging the lifespan of gearbox bearings, Semcon and Sporveien are also investigating:

Oil purity with the help of advanced acoustic technology and machine learning algorithms

The condition of underground carriage doors, a component that typically needs a lot of maintenance due to wear. In this project, acoustic technology is used to assess the condition of each set of doors.

Future-proofing a complex operation

A holistic approach is needed to transition from a traditional workshop to a digitalised and data-driven operation. It is not only about data management solutions and hardware. Company employees need to be onboard with the upcoming changes and receive the right training. The implementation of a new IT architecture and new ways of working are also required.

“Semcon is supporting Sporveien in many parts of this complex journey. Smarter operations are a prerequisite for Sporveien to fulfil their mission to provide even more public transport to Norwegian citizens,” adds Semcon’s Thor André Dugstad.

Semcon’s deliveries:

Advisory services

Project management

Product development

Simulation

Mechanical testing

Data management and AI solutions

Software development

Mechatronics