Case

Carbon footprint of Wellspect's catheter cut in half

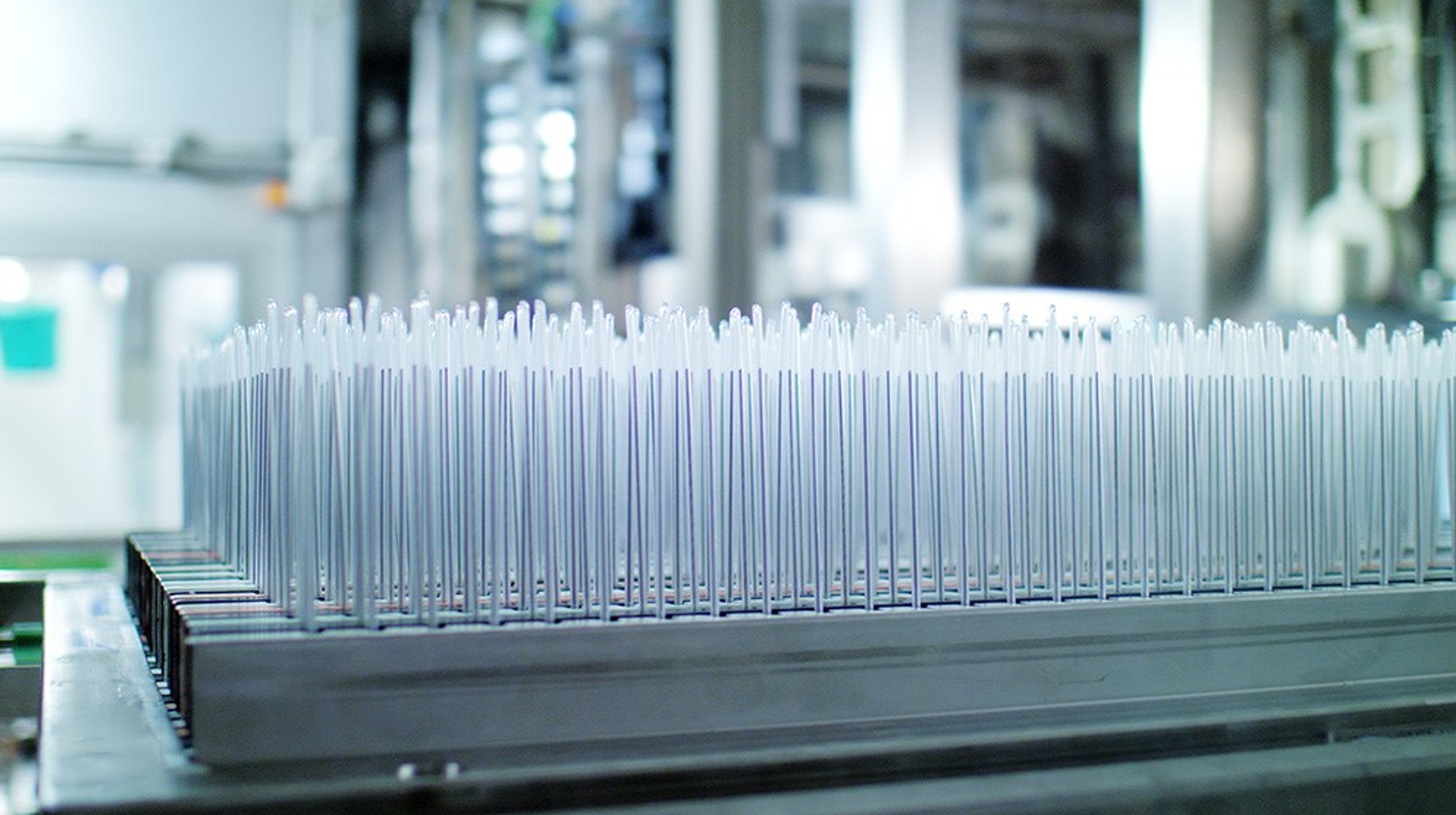

Semcon’s life science experts provided support to the medtech company Wellspect when it expanded its catheter production. The result was both a reduced carbon footprint and maintained quality for the best possible user experience.

CustomerWellspect

IndustryLife Science

CompetencesValidationQuality AssuranceSustainable Business

Background

In 1983, global medtech company Wellspect launched the LoFric® urine catheter. The catheter helps sufferers of urinary tract problems to live active lives thanks to its unique, very slippery coating, Urotonic™ Surface Technology, which makes it gentle and easy to use. Expanding the production made it necessary to replace the process equipment, and Wellspect decided to take an even greater step forward than demanded by the authorities. Semcon provided support with experienced consultants in several areas, in particular with excellence in validation.

A long-term cooperation

Semcon and Wellspect are well known to each other thanks to a collaboration that has continued for over a decade. This has allowed Semcon’s consultants to quickly step in and provide support for the large and resource-intensive project with the new coating process for the LoFric catheters. The strict regulations that govern the Life Science industry require extensive validation and quality assurance for all new products and updates. Semcon has long and solid experience in this type of process, which facilitates contributing to an efficient process to swiftly bring about new, smarter products for the benefit of end users. Erik Bengtsson, who is Project Manager at Wellspect and responsible for the project, emphasises Semcon’s role in the validation work.

“Semcon has played an important role in several different projects for many years, taking great responsibility for validation, in particular in this project, which has included in-depth validation collaboration”, says Erik Bengtsson and continues:

People in focus

The goal of the new coating process was to reduce the carbon footprint, but the most important requirement for the project was to maintain quality – the unique characteristics of the catheter had to be the same as before. This meant that the project faced great challenges, although for Wellspect, there was never any other option. Its vision is to make a real difference every day to the lives of everyone who needs its products.

This philosophy is shared by Semcon, which also puts people first, and views technology as a tool for creating value for both people and the planet. Jenny Algelid Bengtsson is validation expert at Semcon, and in recent years has worked for Wellspect on the project with the new coating process. She is very pleased that she had the opportunity to participate in the project from day one.

"At Semcon we place great emphasis on both sustainability and people, helping development for the user. This applies to Wellspect too, and sharing common values makes it easy to participate and create value in a short time." says Jenny Algelid Bengtsson, consultant at Semcon.

Full speed ahead

While the project has been very resource-intensive over a long time, Wellspect’s other activities have continued as usual. The company is growing and has several ongoing simultaneous projects, which involves varying needs for skills. Semcon has contributed with consultants in both the short and long term in more areas than validation, and has contributed to Wellspect keeping up the momentum in all of the projects. Among other things, Semcon has provided support to Wellspect with project managers in production and R & D, as well as validation engineers and subproject leaders.

"We are grateful for the opportunity to be involved in and to contribute to the major environmental improvement involved in this project. In addition, many people depend on these products in their everyday lives, which further emphasises the importance of this work." says Anna Nordelöf, Area Manager at Semcon.